The ISO standards, in comparison, typically only address a single topic at a time. The Y14.5 standard has the advantage of providing a fairly complete set of standards for GD&T in one document. This article is based on that standard, but other standards, such as those from the International Organization for Standardization (ISO), may vary slightly. One such standard is American Society of Mechanical Engineers (ASME) Y14.5. There are several standards available worldwide that describe the symbols and define the rules used in GD&T.

Two examples are linear dimensions and feature control frames using a datum reference (both shown below).

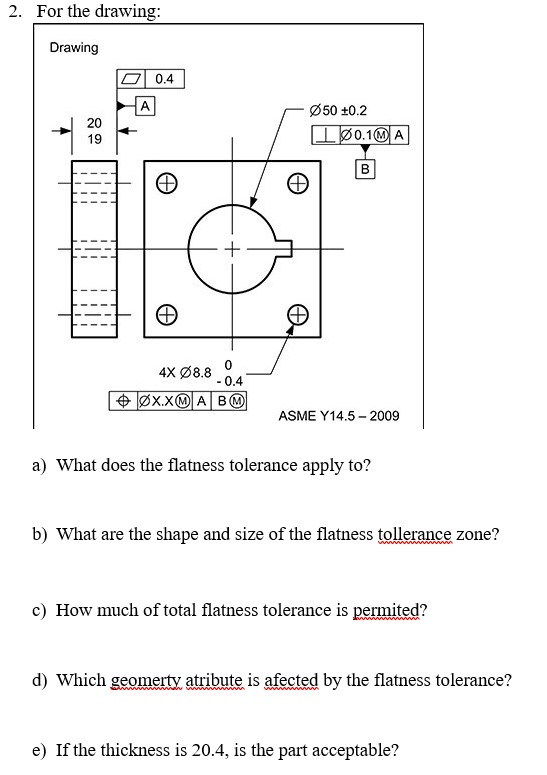

Tolerancing specifications define the allowable variation for the form and possibly the size of individual features, and the allowable variation in orientation and location between features.Dimensioning specifications define the nominal, as-modeled or as-intended geometry.GD&T is used to define the nominal (theoretically perfect) geometry of parts and assemblies, to define the allowable variation in form and possible size of individual features, and to define the allowable variation between features. It tells the manufacturing staff and machines what degree of accuracy and precision is needed on each controlled feature of the part. It uses a symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describe nominal geometry and its allowable variation. Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances and relationships. Example of geometric dimensioning and tolerancing

0 kommentar(er)

0 kommentar(er)